News

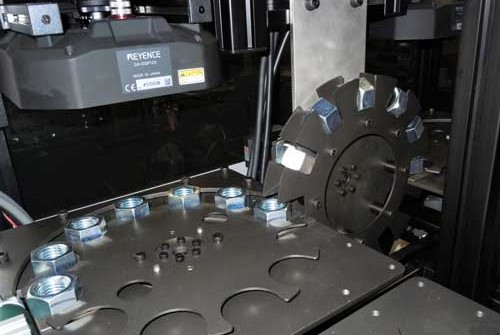

Japanese K&K Engineering Successfully Develops QV-7108・3D Inspection Machine

Add to my favorite

2020-12-21

The latest model "QV-7108・3D" developed by K&K Engineering Corporation is the first inspection machine in the Japanese fastener industry that comes with a 3D photographing function. The illuminating device installed to the camera on top of the existing model "QV-7108" casts on and off a net-shaped light on workpieces and analyzes the reflected light in real time to generate 3D graphics. The different heights on a workpiece are color-coded. The workpiece's 3D shape is analyzed to check its burrs and thickness deviation.

"QV-7108・3D" can check (pre-oiled) nuts up to M24 in nominal diameter. For M24 nuts, it can check 100 pieces per minute. It has two index tables with an inverting device in between to flip over the nuts.

"QV-7108・3D" can check (pre-oiled) nuts up to M24 in nominal diameter. For M24 nuts, it can check 100 pieces per minute. It has two index tables with an inverting device in between to flip over the nuts.

K&K Engineering Corporation

3D inspection machine

burrs

thickness

尺寸檢測機

毛邊

厚度