Industry Activities

New Choice for Fastener Surface Treatments- ZHENG TUNG ENVIRONMENTAL PROTECTION TECH Launches All-inclusive Fastener Surface Treatment Service

Add to my favorite

2022-03-18

Taiwanese leading steel bar, billet, and wire coil manufacturer Hai-Kwang Group founded a new subsidiary “Zheng Tung Environmental Protection Tech. Co., Ltd” in the end of 2021, officially announcing the service extension to surface treatment for the downstream fastener industry. Different from several other domestic providers dedicated to only one service, Zheng Tung will gradually offer heat treating, plating & coating, wire drawing/spheroidizing/cleaning, phosphating, and even waste water treatment service in the near future, which not only creates a new collaboration model, but also builds up a well-integrated supply chain.

EPA absolutely will become stricter than ever, so it is much more important to work with fastener surface treatment providers that better fit with modern EPA as quick as possible. However, some domestic decades-old treatment providers having old-fashioned equipment often face difficulties in making complete improvement and can only adopt temporary solutions to fix common issues, which, after Taiwanese Government starts to launch 3 phases of stricter EPA, will make it harder for them to meet new waste water discharge standards in their own plants or achieve higher competitiveness through process outsourcing, thus increasing uncertainties of lead times and product quality overseas customers care about the most.

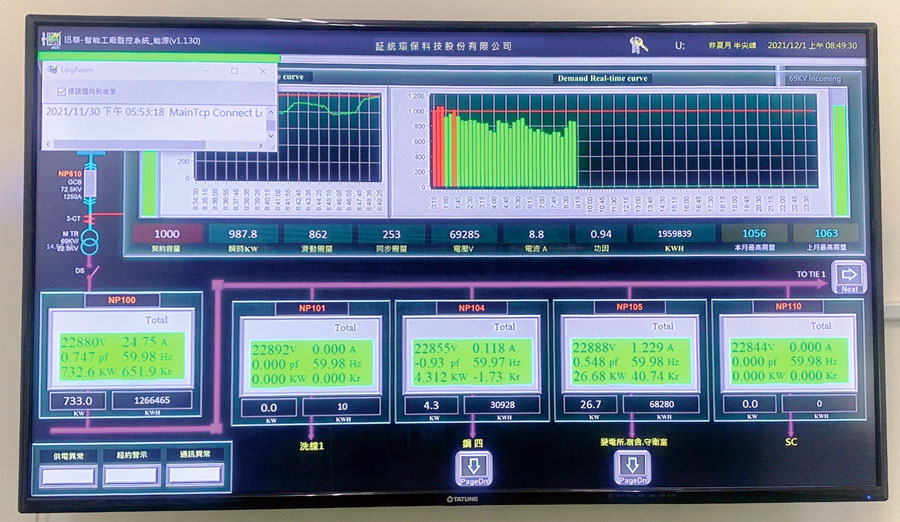

“We own the 47,600 sqm of land for Gr.1 industrial use, 69KVA super high voltage power supply & storage control systems to ensure continuous power supply in manufacturing, and advanced EPA-compliant waste water facilities (incl. 6 sets of EDR waste water recycling facilities and a 16,000 m3 cistern for water shortage), as well as enough capital, technology, and talent resources. With so many favorable conditions in terms of land, power, water, and labor, we could be more competitive than other industry counterparts. Furthermore, Hai-Kwang Group offers service including wire production and has been in collaboration with the fastener industry (the downstream of the steel industry) for more than 2 decades, so entering this field at this moment is of more significance. It can also play a role complementary to the supply chain in satisfying fastener customers’ demands, easing the imbalance between the supply and the demand, making contribution to the healthy development of Taiwanese fastener industry, and most importantly, making customers feel no worries about fastener treatments and willing to keep operations in Taiwan,” said Zheng Tung CEO Tsan-Ming HUANG.

Zheng Tung’s 4 Heat Treatment Lines have become operational since the end of last year and the other 2 electroplating lines have been almost ready to be activated. It also plans to add more lines for electroplating, coating, and waste water treatment this year to offer customers more comprehensive service. In addition, benefited by the proximity to Taiwan CSC, many wire supply sources in Pingnan Industrial Park, and ports where overseas wire are imported, it also plans to set up systems for pre-manufacturing wire drawing, spheroidizing, and phosphating by 2023, which can greatly reduce customers’ time and shipment costs. Zheng Tung introduced the most advanced and highly efficient Taiwan-made automated equipment, and as it has a wide factory area, customers’s products can be shipped in and out flexibly without delaying the lead time for 1-2 months or even longer.

“We hope to control the time from order acceptance to final delivery within 1.5-2 months (approx. 7-10 days per process). Currently we can process around 2,500 tons of screws a month. We’ll also add more new lines in due course to respond to customers’ demands and expect to reach around 10,000 tons a month. As for electroplating, we adopted the highest ammonia-nitrogen control standard to design our waste water system and expect to process around 22,000 tons a month in the future. We also expect that our future wire processing lines can reach 20,000 tons a month, as well as 5,000 tons a month respectively for phosphating and coating, ” said CEO Huang.

“We have state-of-the-art facilities, as a result, we can give customers more accurate lead times and customers can keep more updated with the status of their orders. What’s the most important is that customers can feel rest assured to commit their products to us,” said Chairman Wei-Han, HUANG.

Zheng Tung’s heat treatment lines can process many widely applied products such as self-drilling screws. It also plans to offer multiple processing solutions that allow customers to send products to Zheng Tung after forming after it completes trial runs of its electroplating lines this year. Customers don’t have to worry about which surface treater should be responsible for defects anymore. This not only demonstrates its confidence in its own technique and service, but also offers customers 100% guarantee of reliable quality.

What’s worth mentioning is that Zheng Tung introduced the Smart Factory 4.0 platform from its parent company instead of adopting conventional ways of other fastener surface treaters and allows customers to book online for treatments. In the future, it will also integrate with smart production scheduling, Big Data, order tracking, logistics, supply chain matchmaking and production control systems and adhere to its mission statement with the principle of not distorting the market prices to create the biggest competitive edge for all.

“It’s almost impossible to find a substitute which has the same advantages as we do. Take the solar panels, heat treating oil & waste water recycling, and rain filtering systems for example, we invested a lot in building up these systems to the best, which is almost impossible for other small enterprises. Due to this reason, customers working with us don’t have to worry about the possible limited power supply or water shortage in the future,” said CEO Huang.

Zheng Tung has also set a goal for 2022. It expects to increase the utilization of heat treatment, electroplating and coating and capacity to 80%, reduce the defective rate to below 1%, and cultivate its employees’ profession and knowledge of multiple manufacturing procedures. Meanwhile, its also hopes to work and grow with the fastener industry and create mutually-shared value with customers and counterparts to build up a healthily developing fastener supply chain.

証統環保科技

表面處理代工服務

ZHENG TUNG ENVIRONMENTAL PROTECTION TECH

fastener surface treatments

Industry Activities

2022-03-18

Subscribe