Industry Activities

Yi Sheng Ultimate Tailor-made Self-drilling Screw Forming Machine. Exclusive Feature: Welding Before Pointing / Twin Oil-recycling Troughs

Add to my favorite

2022-03-18

Complete Service — Manufacture, Maintenance & Repair, Installation

Located in Gangshan District of Kaohsiung City, Yi Sheng Machinery manufactures self-drilling screw forming machines and provides maintenance/repair, related components and installation service. The company is specialized in 100% customized forming machines. Using one-stop equipment, it mainly manufactures high quality and high efficiency self-drilling screw forming machines, as well as rivet machines and anchor machines, providing highly flexible and tailor-made service.

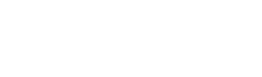

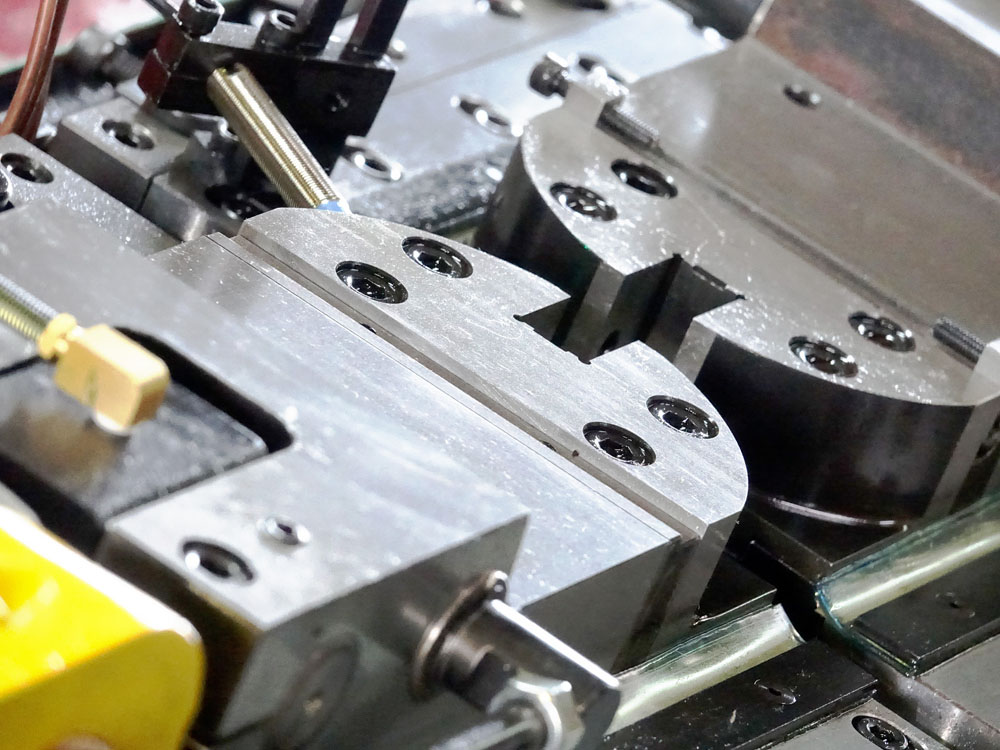

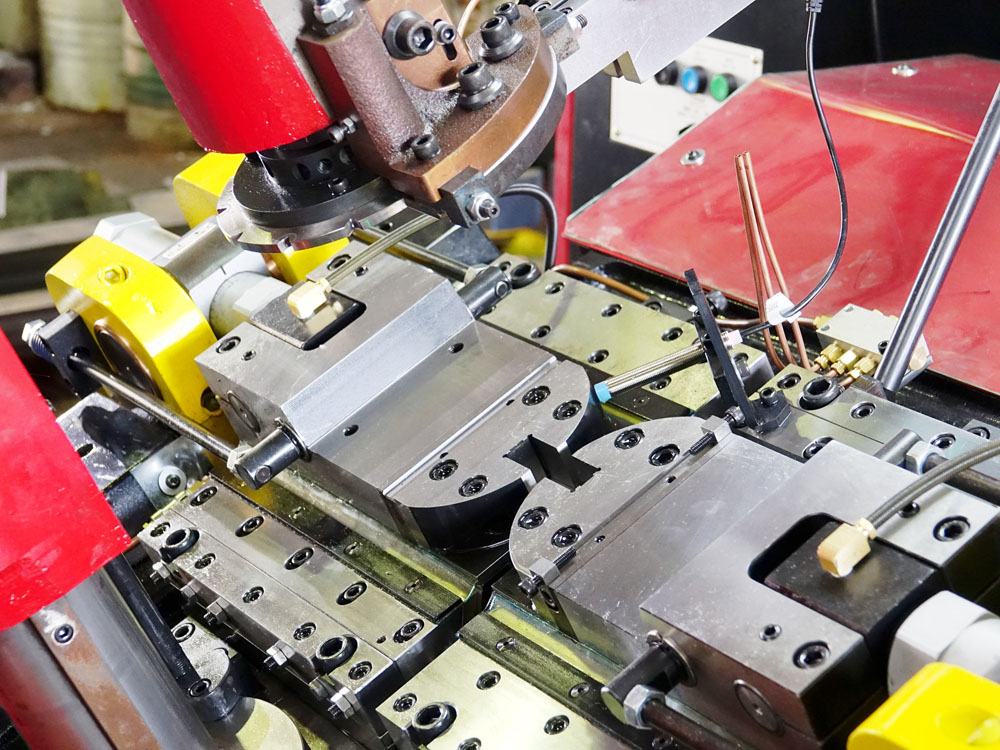

YS250Z Self-drilling Screw Forming Machine

Improved Culmination of All Models Available on the Market

With four years of devotion, this work of perfection came out of a design drawn by the owner and developer Mr. Kai Hsiang Hong, combining the strengths of all models available on the market and eliminating the weaknesses. With a manufacturing process different from common self-drilling screw forming machines, YS250Z welds wire rods before pointing them. This creates more precise concentricity of screws and better torque performance than the conventional manufacturing process where pointing precedes welding. It is the innovative process exclusive to Yi Sheng Machinery.

The new twin troughs structure is solely designed for bi-metal and stainless steel screws. Given that manufacturing heavy-duty screws requires adding chlorinated paraffins, he came up with a twin troughs design to separate oil from water and increase dies life to achieve consistent screw quality.

Highly Customized and Durable

The company has tailor-made a 300mm long bi-metal screws (No. 5) machine before. It is well-acclaimed by many high-end screw manufacturers for its high flexibility, especially for machine durability. Regarding the pull lever, they require using springs with sufficient pound weights to maintain stability. To that, the company imports springs from Germany to increase the life span to 5 to 6 years. Additionally, the material is aluminum-copper alloy with better abrasion resistance than phosphor bronze’s and with much improved durability. Regarding the machine's structure, the company enlarged and thickened the spindle which is made of FCD600. “Our machines could be higher than common mass-produced models, but the material and stability of our machines are nothing that those models can compare to.”

Intuitive, Labor-saving Smart Human Machine Interface

The interface by design provides intuitive user experience by displaying anomalies on the screen to avoid errors made by inexperienced personnel as well as training cost. “Pointing a screw creates a force which changes when the dies are damaged, so we set a test device in our machines which senses the damage and pops up an alert to remind the personnel of checking the dies. The tap’s edge status is more difficult to predict and be detected with optical sorting. Our machines can observe the level of force impact and monitor the width of the edge to determine if it is up to standards.”

Mr. Hong sticks to delivering quality and the best to his clients. “We hear you. Whatever your call is, we will make it work!”

Contact: Mr. Kai Hsiang Hong

E-Mail: a0923243033@gmail.com

鎰晟

複合鑽尾螺絲機

先焊再夾

雙油槽

Yi Sheng

self-drilling forming machine

welding before pointing

twin oil-recycling troughs