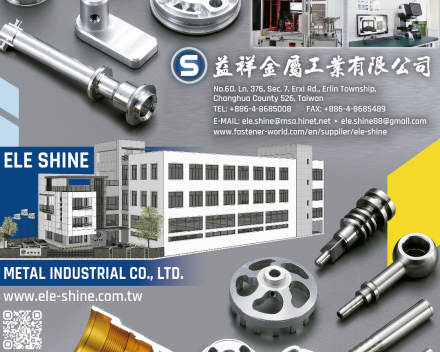

ELE SHINE METAL INDUSTRIAL CO., LTD.

CNC Automatic Lathes Computer Precision Metal Parts Manufacturer

Ele Shine Metal Industry Co., Ltd. was established in 1980 in Taiwan, is a professional computer CNC automatic lathe milling precision metal parts manufacturer.The main products used in computer components,bicycle parts,optoelectronic components ,machine auto parts,gas parts,electronic parts, communication parts,bathroom hardware,machinery, hardware,pneumatic tools,sports equipment,buried

screws and nuts,all kinds of connectors the

high-precision parts manufacturing and processing . From high-speed lathes,automatic lathes,lathe tool path ,and even take heart.CNC lathe and milling at once. Different products require visualization,and provide reliable solutions ! Machining brass,beryllium copper, phosphor bronze,copper,stainless steel,

free cutting steel,alloy steel,steel,aluminum,

plastic and other materials,but also with the product as anodizing,polishing,vibration,magnetic resonance imaging,plating,Black,passivation,heat treatment, chromate,phosphate,coating and other surface treatment , processing capacity from OD 2 ~ 42 mm, length 600 mm of precision metal parts can be.And through the ISO 9001:2008 international quality certification,

called the most sophisticated and most competitive manufacturer of precision metal parts.

Adhere to the professional and innovative spirit of enterprise services,continue to provide customers with the most competitive in the market right products.

We view our customers as partners; to "produce high quality parts" as the chief operating principle. 32 years of market experience, continuous improvement expertise, providing high quality innovative products, processed products comply with RoHS environmental specifications. We not only provide domestic and international customers with the most sophisticated and most competitive hardware products include surface treatment and assembly and other full-service. Fast and accurate service efficiency, provide better customer service to meet future demand for high-precision machining.