HISENER INDUSTRIAL CO., LTD.

Hisener Industrial Co., Ltd.

New Plant to be Completed in August

/Elevated Capacity in 2021

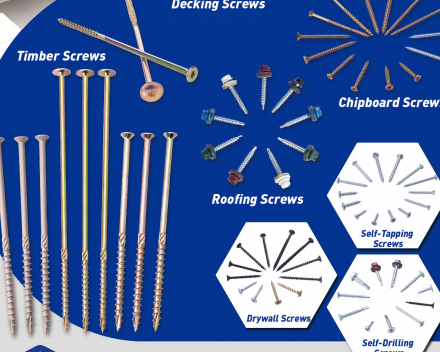

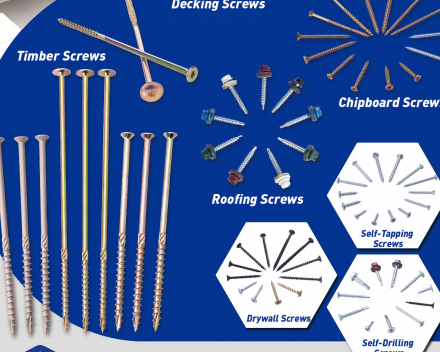

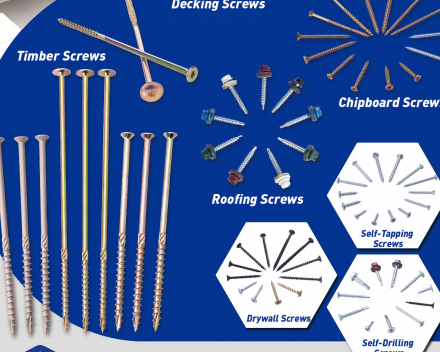

Hisener mainly provides screws.In the last two years it exported a total of 87 thousand tons of screws, up 17%. Now it has become one of the biggest fastener suppliers in the world, offering clients over 4 thousand types of fasteners sold to Europe (35%), Russia (25%), the U.S.(20%) and South America (15%). It also works with overseas distributors and provides clients with prompt service and premium products, including Timber Screws which sell well in the European DIY market.

It has its own screw factory, packaging line for DIY products and a warehouse. The company can pack 50 containers of products per month. It uses heading machines, thread rolling machines, thread cutting machines, drill forming machines and other equipment purchased from Taiwan. It has dimension measuring instruments, metallurgy analyzers, mechanical testers and surface analyzers in its laboratory for quality inspection to control product quality.

In our interview with General Manager Simon Liang, he brought good news that a new plant broke ground last September and is expected to be completed this August. The new plant will be 26,000 square meters and raise screw capacity to 1,500 tons per month, lifting Hisener to a higher market position.

/Over a Hundred Select Partnering Firms -

Strict Quality Control

The company has 150 partnering firms carefully chosen to help speed up delivery and send products to buyers faster. It offers inventory specifically for Chinese clients so that they can get their cargoes quicker when their demand is urgent.

All the production process is certified to ISO9001 and re-audited and adjusted every year to strictly monitor and control each production process via a digitalized ERP system. It is also certified to CE EN14592 on structural fasteners and CE EN 14566 on mechanical fasteners, and therefore its products are popular among European clients.

/Going for Smart Factory -

Improved Price Competitiveness

Simon wants to build his company into a futuristic smart factory. Ever since he adopted an automatic inventory system, the company has successfully integrated the whole production process, which greatly reduces logistics costs and improves operating efficiency of the plant to make products more competitive. “We will continue to go further down the fastener industry and invest more in R&D, production, and DIY product packaging. We always put our clients first and continuously offer them better service to add up their values.”

Hisener Industrial Co., Ltd, founded in 2004 is based in Haining, Zhejiang (China). It started the business with threaded rods manufacture and the high quality products and excellent service it offered later helped the company gradually gain worldwide reputation and went on the road of business transformation. Considering the ever-growing fastener market in recent years, the increasing and more diversified demand for fasteners from customers, and with an aim of satisfying global customers’ various needs of bolts, screws, nuts, etc., Hisener set up a division in 2006 particularly dedicated to int’l trade and purchase and reinforced collaboration with other fastener producers at the same time in order to expand its product range. Later, with its sales and product range keeping growing, Hisener set up a new screw factory in 2010 and was also certified by ISO9001:2008 in 2011. Such significant improvements and growth over the past years made Hisener continuously appreciated by the industry. Main products of Hisener include wood screws, self-drilling screws, self-tapping screws, roofing screws, chipboard screws, drywall screws, machines screws, deck screws, and etc., most of which are applied in building, furniture and home improvement industries. Its average monthly capacity reaches around 500 tons, the monthly production of threaded rods is about 1,500 tons, and the annual export value lands at 50 million USD (all of these figures are still increasing year after year). In 2017, Hisener reported up to 57,000 tons (approx. 68 million USD) in total sales (incl. outsourcing) and sales were mostly generated from screws (30%), threaded rods (20%), nuts (20%), bolts (17%), washers (8%) and so on.

Being Optimistic to Future DIY Market, Hisener Continually Conducts Its Factory Upgrade Programs

The DIY market in Europe, USA and Asia has been in a sharp growth in recent years, which also boosts the demand for home improvement fasteners. For Hisener, whose products are mostly applied in home improvements and construction, this would be, with no doubts, substantial business opportunities. As a result, Hisener added the new packaging line for DIY products and a warehouse in 2015 and gradually focused more on the home improvement fastener market. Thus far, Hisener has been able to process customers’ various packaging requests. On the other hand, with an aim of offering customers better product/service quality and bringing its capacity into full play, Hisener then carried out an array of in-plant upgrade programs started from 2017, including installing processing equipment with better quality at reasonable prices from Taiwan, e.g. heading, thread rolling/cutting, and drill forming machines, making its capacity hike from 300 tons per month to 500 tons per month, that is, an over 60% increase! All the aforementioned not only made Hisener spend money wisely, but also maximize its capacity and efficiency within the shortest time. Hisener also has its own lab installed with dimensional measurement devices, metallurgical analysis instrument, mechanical testers and surface analysis machines to inspect depth, hardness, straightness, tension, drilling speed, torque/torsion, plating, etc., which ensures perfect quality control before delivery to customers.

Speaking of the current operation and capacity improvements in the company, General manager Simon Liang said, “We moved our DIY warehouse originally located in Haiyan to Haining in 2017 and integrated it with our screw factory. In addition, 3 automated packaging lines were also added for increasing the packaging capacity. Now we could offer various packages for 4,000+ types of fasteners and the monthly pre-packed items could reach 20-25 containers. We could also offer different packaging services for DIY products sold to building materials stores.”

ISO & CE Certified, Hisener Focuses on Sales in Europe and USA

Currently, 95% of Hisener’s products are standard parts and the company exports about 5,000 tons of fasteners per month. Besides outsourcing from around 150 subcontractors, Hisener also produces 1,500 tons of threaded rods and 500 tons of screws per month on its own. As a fastener producer whose products are 100% for export, Hisener exports 35% of its products to Europe, 30% to Russia/Ukraine, 20% to USA, 13% to S. America and 2% to other regions. In order to ensure high quality of products and well-controlled manufacturing procedures, Hisener was successfully certified to ISO9001:2015 and CE EN14952, which not only proves the technique and management of Hisener on the one hand, but also consolidates the irreplaceability of the company on European/U.S. customers’ minds on the other hand. When it comes to marketing, Hisener will also exhibit at Int’l Hardware Fair Cologne, Fastener Fair USA, National Hardware Show, Taiwan Int’l Fastener Show, and Torque Expo Coventry, in anticipation of establishing partnerships with more customers.

Hisener contact: Simon Liang (General manager)

Deck Screws

Wood Screws

Roofing Screws

Chipboard Screws

Concrete Screws

Deck Screws

Wood Screws

Roofing Screws

Chipboard Screws

Concrete Screws

Self-Tapping Screws

Machine Screws

Self-drilling Screws

Chipboard Screws

Drywall Screws

Self-Drilling Screws

Roofing Screws

Self-Tapping Screws

Window Screws,Wood Screws

Decking Screws,Machine Screws

Concrete Screws

Collated Screws

Timber Screws

Stainless Screws

Dowel Screws