Industry Activities

by Dean Tseng, Fastener World

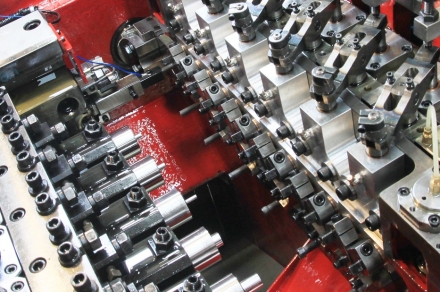

Zen-Young Industrial Co., Ltd opened business in 1998 focusing on developing and producing screw and washer assembly machines (direct-press-in type & screw-in type). Later on its business extended to anchor sleeves, gunpowder powered nail guns, other customized assembly machines and packaging machines. Zen-Young has a strong drive for R&D targeting 3 objectives: (1) Machine appearance manifests a modern, high-tech and high-value feel; (2) Rapid and smooth dies exchange and operating procedure; (3) Production speed exceeds client expectation. The company mainly targets Europe (Germany, UK, France, Poland, Russia), but as demands in Turkey and Vietnam are increasing, it will target its sales focus on these regions this year.

Ongoing R&D Brings High Speed Assembly to a Whole New Level

In General manager Mr. Joey Yang’s perspective, Machine manufacturing shares the same mission statement with the catering service industry. “Client feedback is important. If you don’t get a positive recognition from clients within a couple of months and cannot adjust business strategy in time, the market will eliminate you. Therefore, we put our focus on how to improve machine operation, debug and refine machine structure in order to solve clients’ problems. For instance, at the initial stage of development, our anchor assembly machine couldn’t assemble slightly bent and deformed screws and anchors. We redesigned the machine so it can assemble such screws and anchors that are slightly bent and deformed within an acceptable range. Meanwhile we boosted the machine’s assembly capability to as fast as 700 pieces per minute!”

Besides screw and plastic anchor assembly machines, last year Zen-Young rolled out the highly-acclaimed high speed nail and cable clip assembly machine that switched from intermittent to continuous assembly mode, boosting speed from 80-160 pcs to over 500 pcs per minute. The machine comes with a sorting function and human machine interface. It can display error message, location and reports, and has multilingual support.

Zen-Young also provides high speed collated screw assembly machines that assemble as many as 2,000 screws per minute. The plastic strip that the company developed applies to various brands of electric tools. According to Mr. Yang, Zen-Young started off doing contracted assembly for domestic screw makers and later started to take orders due to numerous inquiries from overseas clients. Now with an integrated list of collaborative screw suppliers, Zen-Young provides high quality collated screws domestic and abroad.

Prepared to Support Future Factories & Client Demand

In Zen-Young’s perspective, as we are entering the era of Industry 4.0, factories will be heading for unmanned manufacturing. Other than reducing labor cost and improving efficiency, the most important thing is to avoid human error, so machine manufacturing will orient for customization and automation to rapidly tailor to clients’ demand. For this purpose, Zen-Young puts an emphasis on service during the manufacturing process. It provides 3 dimensional dynamic simulation graphs, machine specs charts and the specs for peripheral air compression equipment and electricity consumption. After test trial by technical staff, it can offer test run through online video cam or recorded test videos for pre-shipment confirmation of clients who are unable to visit the plant. Regarding after-sale service, it numbers every machine and component and stores all data on computers that can trace back to the very first machine Zen-Young produced.

Latest Business Plan

Zen-Young develops new machines every year. This year it will focus on developing a powder painting line that can directly take over from washer assembly machines. Besides painting service for self-drilling screws with attached bonded washers, it can color paint one single screw or nail head. It also adds the functions of screw rust prevention and nail length categorization. These will save tremendous labor cost for the fastener industry and shorten the time for screw head painting to shorten lead time. Zen-Young stresses product core value and dismisses low price competition to offer user-friendly, simple-structure, few-expendables, and high-productivity machines and after-sale service at reasonable prices. This year it will attend Taiwan International Fastener Show, and it plans to display machines in German shows in the future. Zen-Young’s R&D momentum is sure to continue to amaze global clients!

Zen-Young contact: Sales manager Angela Chen

E-mail: zenyoung@ms72.hinet.net

Subscribe