Industry Activities

Motiontite Bolt For European & American High-end & General Applications

Add to my favorite

2023-01-16

Made with Innovative Japanese Thread Technology

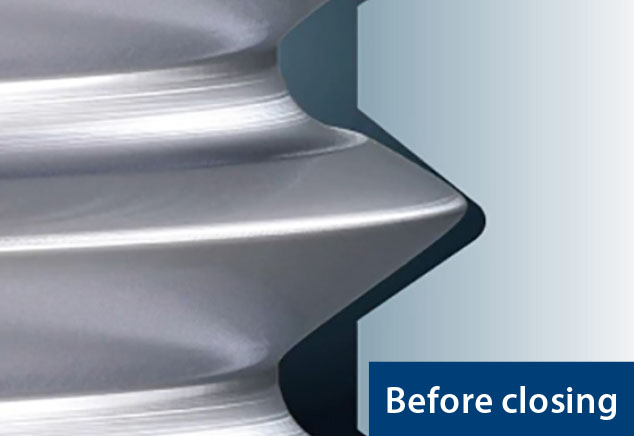

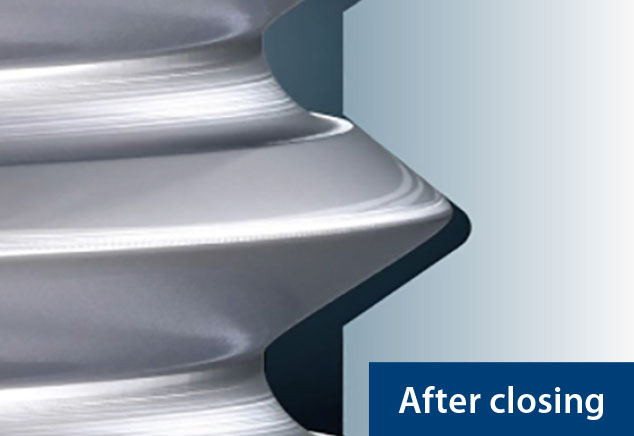

In our last interview with Art Screw president Mr. Kou Matsubayashi last September, he revealed his game-changing combo-technology with MOTIONTITE. It is an all-in-one solution to resolve loosening, rupture and galling in one shot. You see, it isn’t just one function. It is multi-functional. All you need to do is to drive it in with torque, and the threads work and tighten like using a spring.

It is a fantastic feature attracting the eyes of top Japanese corporations who now increase purchase from him, which triggered his thought that MOTIONTITE could also work for overseas customers, so he thought to sell overseas. It came to him that Europe and the U.S. seek eco-friendly fasteners that are free from using adhesives. These regions, like Japan, are the heartlands of automakers, so he is kicking off marketing there for starters in 2023.

You Can Manufacture & Sell MOTIONTITE

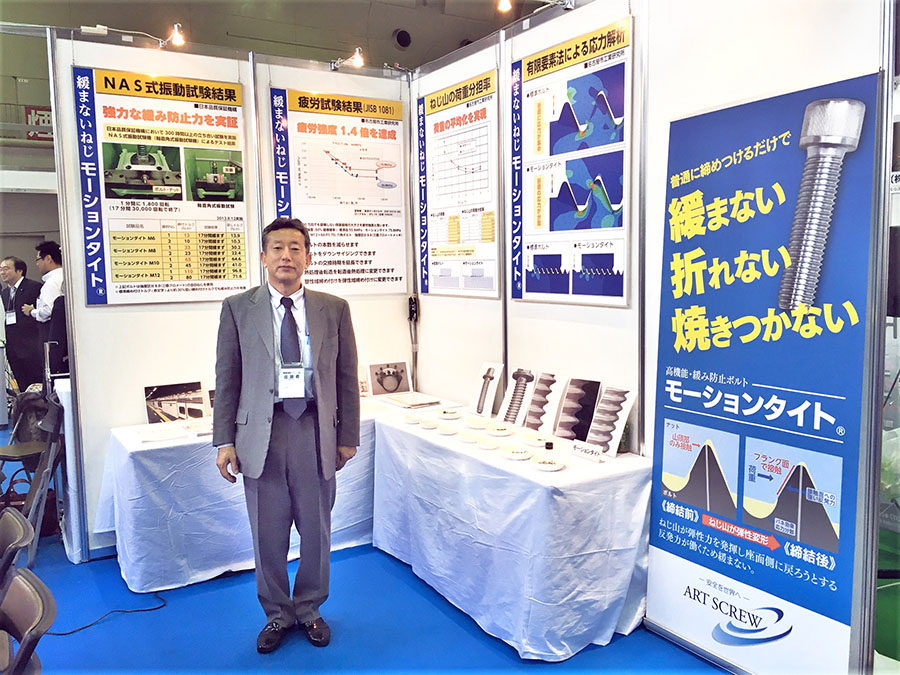

(Art Screw President Kou Matsubayashi)

It is a well-known fact that Europe and the U.S. are stringent about quality and yield. “I’ve been running my plant and threading automotive bolts for over 30 years in Japan. As far as quality and yield, Japan is more picky. MOTIONTITE has been used on motorcycle engines, wind turbine blade bolts, satellites, medical devices, even semiconductor manufacturing devices and more, so it speaks for itself. I’d like for European manufacturers to test it out if they wish so,” said Kou. MOTIONTITE isn’t limited to high-end application only, it is open for use by general industrial customers as well.

He is seeking overseas partners to manufacture and sell MOTIONTITE in their local markets. By them using the thread rolling dies and ring gages directly from Kou, MOTIONTITE can be manufactured anywhere on the globe. “It wouldn’t be cost-effective to manufacture the bolts in Japan first and then export them, but manufacturing the bolts at customers’ locations makes it possible to provide the safest and the best-performing anti-loosening products, so I’m welcoming European and American bolt makers to manufacture and sell MOTIONTITE,” said Kou.

New Product Coming up

Kou is working on a hex socket set screw and tapping screw with brand-new thread shapes. Before that, he could be starting sales of size-reduced bolts which are a combination of Grade 13.9 KSDN4 material and a newly-developed thread shape which doesn’t loosen at all in Junker vibration tests. Given the high axial force and loosening resistance, customers can change from M14 to M12 or from M12 to M10 bolts. The bolts can be electroplated and therefore can be used in various applications. They can be made smaller or in less volume to be lightweight, “so I recommend using them to fasten EV battery packs,” said Kou.

Last but not least, Kou has launched an English website for Art Screw. “I’ve packed the website with abundant information for your reference. Drop your request from my homepage or contact through my email if you have any questions,” he said. Web visitors will find test data, technical diagrams and demonstration videos there.

Contact: President Kou Matsubayashi

Email: info@artscrew.co.jp

Motiontite螺栓

日本Art Screw

松林興董事長

歐美高端市場

通用市場

Motiontite bolt

President Kou Matsubayashi

European and American high-end markets

general industrial use market

Industry Activities

2023-01-16

Subscribe