PPG - Bringing Innovation to the Surface

Bringing Innovation to the Surface

Over the past 25 years, the Taiwan fastener industry has matured from supplying standard parts to highly complex fastening products. Taiwan is now the global “fastener capital”, providing its products to over 200 countries on 5 continents. It was Taiwan’s global presence in the market that enticed PPG to open a fastener electrocoat application factory there. Alltech Engineered Finishes is the only PPG applicator in the Asia market. Alltech Engineered Finishes is centrally located in Kaohsiung and opened in 2006. Alltech provides finish services to the construction, automotive, and light industrial markets. This year, Alltech celebrates its 10th anniversary in operation!

PPG – Bringing Innovation to the Surface

Headquartered in Pittsburgh, PPG supplies paints, industrial coatings, chemicals and glass products to global customers in the construction, heavy duty equipment, automotive, transportation, appliance and consumer products industries. Founded in 1883, PPG employs 47,000 people globally and is the world’s largest coatings company. In 1976 PPG pioneered the development of cathodic and anodic electrocoat technology for use in the automotive industry. PPG coatings are recognized as the leaders in the industry. In addition to thousands of patents, PPG continues to develop its product lines through its own research and development center in Allison Park, PA.

PPG technical support is a complete global network. In Taiwan, Alltech Engineered Finishes is a major cog for Asia Pacific. Julia Lin, PPG Business Manager for Alltech describes the Alltech mission as "flying down from the sky, hit the ground running. We know that as long as there are products with rust/corrosion and appearance requirements, you can find PPG for help. More importantly, Alltech provides an environmentally friendly process and product to meet our customer demands”.

Electrodeposition Coatings??? Find out more…

For years, the automotive and aerospace industries have demanded the electrocoat technology. Electrocoat is a paint consisting of water based solution of pigment, resin, water and additives. Application deposition can be anodic or cathodic. Electrocoat products can be epoxy based, acrylic based, or a hybrid of both. Each type of electrocoat has its specialty end use and advantages.

Upgrade coating quality

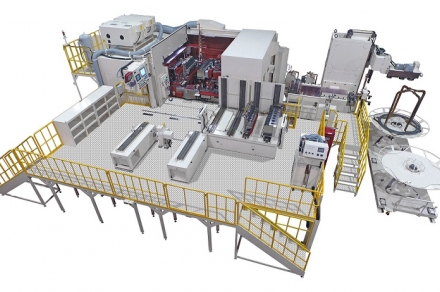

Fasteners and small metal parts can be uniformly coated to avoid recess fill or thread galling product problems, PPG Alltech uses the latest generation of cathodic epoxy electrocoat for coating fasteners and small metal parts.

Excellent corrosion resistance

Different requirements require flexibility of performance. PPG electrocoat systems can reach a salt spray corrosion resistance for 2000 hours or more, and have the ability to reach a minimum of 15 cycles of Kesternich test.

Torque modification coating

PPG electrocoat is also offered at Alltech with a built in torque modifier, easing installation and meeting the torque tension demands of various industries.

Environmentally Friendly Operation and Product

Looking into the future, Alltech is very optimistic about Taiwan's fastener market. By continuing to look forward, PPG and PPG Alltech strive to improve on its offerings to enhance its manufacturing sustainability. Through monitoring its process and product, Alltech hopes it is planting the seed to help the Taiwan fastener dominance continue.

Subscribe