Art Screw- Creator of “Anti-loosening” & “Unbreakable” MOTIONTITE Bolt

Starting as a thread rolling company in 1991 in Nagoya, Art Screw was officially founded in 2003 for developing anti-loosening screws. With the collaboration with Nagoya Municipal Industrial Research Institute, Art Screw began selling MOTIONTITE in 2014. MOTIONTITE gained publicity for attaining 2 features: anti-loosening and anti-rupture. Here, Fastener World Magazine had a close-up interview with the creator, president Mr. Kou Matsubayashi. Below we will look at the features of MOTIONTITE which is now patented in 11 countries.

First, Tackle the Top 2 Complaints

“The top complaints on screws is the problem of loosening, followed by the problem of rupture. Solve these problems, and most complaints will be gone.” But how do we do that? The president said he thought of a basic shape in which the thread crests contact the female threads to trigger spring reaction force, but he suffered seeking the right combination of inclination angle to the bearing surface and the size of root shape to exert the threads’ spring reaction force. He altered the inclination angle degree by degree, coupled with various root shapes, made 200 types of dies, repeated vibration tests and stress analyses and finally found the best shape to absorb vibration and impact.

Creating Threads of “High Fatigue Strength + Consistent High Axial Force”

By combining inclined threads and a large root shape, the load on the 1st engaged thread was reduced from one third to one fourth of the total load, and the stress deconcentrated from the root. This increased the fatigue strength by 20% and gained a consistent, less variable and high axial force. The drawback of a common screw is the structure in which the first 3 threads bear 70% of the load, so stress deconcentration can cover only as much as the nominal diameter length. Take a 15mm/M6 x 1.0 threaded rod for example, stress deconcentration would reach the first 6 threads but the 7th and following threads would be merely in a state of light contact. As all the threads of MOTIONTITE can attain reaction force, the longer the engagement length, the better effect is gained.

High Performance Available at the Price of Common Bolts

“MOTIONTITE is significantly different in operability, price and performance.” It is much cheaper than anti-loosening nuts and adhesives, and about the same price as mass-produced bolts. It has some additional features: (1) Stress deconcentration prevents broken-off bolt heads; (2) Threads' flexible transformation restrains spring reaction, (3) No abrasion damage; (4) No single-side contact; (5) No inclined bolt insertion; (6) lightweight. With specified threading dies and ring gages, MOTIONTITE can be produced in the same specification (M2.5-M16) across the world. In Japan it is widely applied on scooters, semi-conductors, factory equipment, etc. Since it has exactly the same operability as a common screw, it can be used for fastening on any production lines. There is no other bolt like this one that won’t loosen from plainly fastening it.

Making MOTIONTITE the World’s De Facto Standard

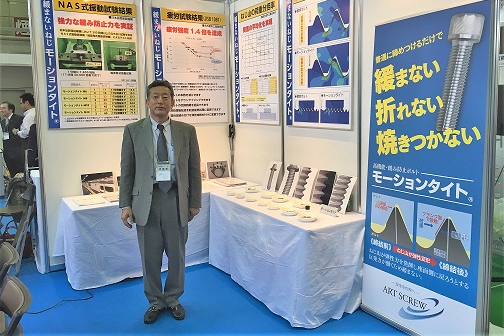

This year Art Screw signed a manufacture and sales contract with overseas bolt makers (Taiwan Fwu Kuang Enterprises and Anchor Fasteners Vietnam). Now the company is seeking to contract with American and European screw makers, and looking for R&D partners willing to solve together the loosening problem of dental implant abutment. Aiming to be a screw innovator, Art Screw has developed a new screw shape with 1.5 times higher fatigue strength which is expected to be announced next year. The president will exhibit at Osaka M-Tech, Nagoya TECH Biz and Taiwan International Fastener Show. Look forward to the live demonstration of MOTIONTITE on the shows.

Art Screwʼs contact: President Mr. Kou Matsubayashi

E-Mail: info@artscrew.co.jp

Subscribe