HISENER INDUSTRIAL CO., LTD.

About Company

HISENER INDUSTRIAL CO., LTD.

CHINA

No. 1, Gushan Road, Changqiangshan Industrial Park, Ganpu, Haiyan, Zhejiang, China

86-573-8737 9889

86-573-8737 9616

Please login

Model / Specification

Country of Origin

CHINA

Surface Treatment

Material

Alias

Patent

Head Marking

Capacity

Minimum Order Quantity

Detailed Description

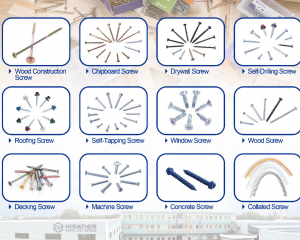

With more than 150 partnering suppliers globally, Hisener is one of the world's largest fastener suppliers. In 2019, the company successfully refined its best-selling wood screws which made a brilliant debut at Fastener Fair Stuttgart. In August 2022, the company completed a new 32,000-square-meter automated and smart factory, housing more than 270 machines to enable triple production capacity, as well as an additional manufacturing line for stainless steel products. In 2023, a dedicated line was built to develop bi-metal screws to meet customer demand for high-performance screws. At this stage, Hisener has perfectly achieved a corporate structure combining manufacturing, trading and R&D, coupled with the previously obtained ISO 9001 and CE certificates to provide over 4,000 types of fasteners to customers in Europe, Russia, the U.S. and South America.

In February 2024, the company released big news that it is all in on an upgrade towards carbon reduction. This makes 2024 “the starting year for Hisener’s green manufacturing", and draws a dividing line in the company’s history to start off into a new GREEN era together with the world's industry leaders, and brings Hisener to a place where it leads the Chinese fastener industry into transformation for low carbon and smart manufacturing. Going ahead at the forefront of global trends, Hisener revealed to Fastener World that they are targeting Southeast Asia in this year's global sales expansion tactic!

High Infrastructure Demand in Southeast Asia;

Hisener is Eyeing Indonesia and Malaysia

Large-scale construction projects are being carried out in most parts of Southeast Asia to accelerate urbanization and infrastructure development. In the next 10 years, infrastructure investment in Southeast Asia, covering areas such as construction, power generation via renewable energy, power grids, and transportation, will require US$2 trillion in financing to transition into sustainable development. This March, Australian Prime Minister Anthony Albanese announced an investment fund of 2 billion in Australian dollars to support transition into green energy and construction in Southeast Asia. From here, we can pick up a potential increase in demand for infrastructure fasteners in Southeast Asia, as well as a trajectory of transformation towards green manufacturing, which is in line with Hisener's "green manufacturing" initiative. Hisener will expand sales to Southeast Asia and infuse high quality Chinese GREEN fasteners into new business opportunities in Southeast Asia.

Indonesia has officially launched in January 2024 the plan to move the capital from Jakarta to Nusantara. The demand for infrastructure and residential buildings as well as business opportunities radiating to neighboring countries could be very large in potential. In addition, Malaysia's economy will see an upward trend driven by light rail transit, mass rapid transit and highway projects now in motion. These have become one of the drives for Hisener to choose to go south for sales expansion. Southeast Asia is currently the second largest trading partner for China. Hisener continues to increase efforts in Southeast Asia, while actively seeking suitable partners to increase investment and provide more purchase access for Hisener's global clients. The company will also exhibit in Fastener Expo Southeast Asia in Jakarta, Indonesia, from August 21 to 23, and it welcomes global visitors to booth number D22.

Highlight: Bimetal Screw

In response to the potential rise in construction demand, bi-metal screws will be one of the highlights at Hisener’s booth. This product has an alloy-steel drive portion welded onto a 300 series stainless steel shank, allowing for a maximal 12.5mm penetration to penetrate carbon steel while having the excellent corrosion resistance and ductility of 300 series stainless steel. The alloy steel threads on the drive portion can cut out grooves on a purlin to create effective locking and enhance pullout resistance. Besides performance advantages, the most important thing is that Hisener can offer the best price. The current production capacity of this product is about 50 tons per month, which is not currently completely filled and therefore, there is great room for more capacity to cater to more clients.

Advancement of Hisener! The “3 Ls Initiative”

After the EU fired the first shot with CBAM, the Clean Energy for America Act is in the making. The British government has promised to roll out the British carbon border regulations by 2027. It is estimated that carbon border tax will be introduced in Asia and many countries in the next decade. Hisenser is one of the earliest big companies in the Chinese fastener industry to put forward a declaration of carbon reduction. For the company, carbon reduction is imperative, so it is currently implementing the “3 Ls Initiative”, with the 3Ls being “Lower carbon, Lower carbon, and further Lower carbon”. The ultimate goal is carbon neutrality. The current ongoing measures are as follows:

1. Increase the use of clean energy. At present, solar power can already meet 30% of Hisener's electricity consumption, and more renewable energy will be purchased in the future.

2. Invest more in optimizing product design and craftsmanship to increase energy efficiency.

3. Reduce energy and material consumption by implementing recycling production methods. Recover energy from waste, such as by filtering waste water and oil and reusing it.

4. Develop emission reduction technologies that suit Hisener and continuously reduce emissions.

5. Focus on green procurement to build a green supply chain. Encourage suppliers to optimize logistics, reduce packaging and use more environmentally friendly packaging materials.

6. Establish a carbon emission verification system, use digital means to complete sustainable carbon verification, and establish full-process supervision tracing carbon footprints from raw materials to final products.

7. Already calculated carbon emissions for 2023 and provided the data to EU clients. Carbon emissions will be calculated per quarter in the future and reported in a timely manner as per CBAM requirements.

8. Hisener will apply for ISO14064 and ISO14067 certification. More actions will be taken in the near future.

Witness the Evolution of Hisener Together

The "3 Ls initiative” demonstrates Hisener's determination for green and smart manufacturing which has been officially put into practical action this year. Hisener's mission statement is continuous improvement and pursuit of excellence, so it continues to invest in R&D and craftsmanship. It welcomes global clients to visit and witness its newly established factory and the fruitful achievements of its evolution.

In February 2024, the company released big news that it is all in on an upgrade towards carbon reduction. This makes 2024 “the starting year for Hisener’s green manufacturing", and draws a dividing line in the company’s history to start off into a new GREEN era together with the world's industry leaders, and brings Hisener to a place where it leads the Chinese fastener industry into transformation for low carbon and smart manufacturing. Going ahead at the forefront of global trends, Hisener revealed to Fastener World that they are targeting Southeast Asia in this year's global sales expansion tactic!

High Infrastructure Demand in Southeast Asia;

Hisener is Eyeing Indonesia and Malaysia

Large-scale construction projects are being carried out in most parts of Southeast Asia to accelerate urbanization and infrastructure development. In the next 10 years, infrastructure investment in Southeast Asia, covering areas such as construction, power generation via renewable energy, power grids, and transportation, will require US$2 trillion in financing to transition into sustainable development. This March, Australian Prime Minister Anthony Albanese announced an investment fund of 2 billion in Australian dollars to support transition into green energy and construction in Southeast Asia. From here, we can pick up a potential increase in demand for infrastructure fasteners in Southeast Asia, as well as a trajectory of transformation towards green manufacturing, which is in line with Hisener's "green manufacturing" initiative. Hisener will expand sales to Southeast Asia and infuse high quality Chinese GREEN fasteners into new business opportunities in Southeast Asia.

Indonesia has officially launched in January 2024 the plan to move the capital from Jakarta to Nusantara. The demand for infrastructure and residential buildings as well as business opportunities radiating to neighboring countries could be very large in potential. In addition, Malaysia's economy will see an upward trend driven by light rail transit, mass rapid transit and highway projects now in motion. These have become one of the drives for Hisener to choose to go south for sales expansion. Southeast Asia is currently the second largest trading partner for China. Hisener continues to increase efforts in Southeast Asia, while actively seeking suitable partners to increase investment and provide more purchase access for Hisener's global clients. The company will also exhibit in Fastener Expo Southeast Asia in Jakarta, Indonesia, from August 21 to 23, and it welcomes global visitors to booth number D22.

Highlight: Bimetal Screw

In response to the potential rise in construction demand, bi-metal screws will be one of the highlights at Hisener’s booth. This product has an alloy-steel drive portion welded onto a 300 series stainless steel shank, allowing for a maximal 12.5mm penetration to penetrate carbon steel while having the excellent corrosion resistance and ductility of 300 series stainless steel. The alloy steel threads on the drive portion can cut out grooves on a purlin to create effective locking and enhance pullout resistance. Besides performance advantages, the most important thing is that Hisener can offer the best price. The current production capacity of this product is about 50 tons per month, which is not currently completely filled and therefore, there is great room for more capacity to cater to more clients.

Advancement of Hisener! The “3 Ls Initiative”

After the EU fired the first shot with CBAM, the Clean Energy for America Act is in the making. The British government has promised to roll out the British carbon border regulations by 2027. It is estimated that carbon border tax will be introduced in Asia and many countries in the next decade. Hisenser is one of the earliest big companies in the Chinese fastener industry to put forward a declaration of carbon reduction. For the company, carbon reduction is imperative, so it is currently implementing the “3 Ls Initiative”, with the 3Ls being “Lower carbon, Lower carbon, and further Lower carbon”. The ultimate goal is carbon neutrality. The current ongoing measures are as follows:

1. Increase the use of clean energy. At present, solar power can already meet 30% of Hisener's electricity consumption, and more renewable energy will be purchased in the future.

2. Invest more in optimizing product design and craftsmanship to increase energy efficiency.

3. Reduce energy and material consumption by implementing recycling production methods. Recover energy from waste, such as by filtering waste water and oil and reusing it.

4. Develop emission reduction technologies that suit Hisener and continuously reduce emissions.

5. Focus on green procurement to build a green supply chain. Encourage suppliers to optimize logistics, reduce packaging and use more environmentally friendly packaging materials.

6. Establish a carbon emission verification system, use digital means to complete sustainable carbon verification, and establish full-process supervision tracing carbon footprints from raw materials to final products.

7. Already calculated carbon emissions for 2023 and provided the data to EU clients. Carbon emissions will be calculated per quarter in the future and reported in a timely manner as per CBAM requirements.

8. Hisener will apply for ISO14064 and ISO14067 certification. More actions will be taken in the near future.

Witness the Evolution of Hisener Together

The "3 Ls initiative” demonstrates Hisener's determination for green and smart manufacturing which has been officially put into practical action this year. Hisener's mission statement is continuous improvement and pursuit of excellence, so it continues to invest in R&D and craftsmanship. It welcomes global clients to visit and witness its newly established factory and the fruitful achievements of its evolution.

Message Board