SHUN DEN IRON WORKS CO., LTD.

About Company

SHUN DEN IRON WORKS CO., LTD.

TAIWAN

NO. 26, CHIA SHIN WEST ROAD, KANG SHAN DIST., KAOHSIUNG CITY, 820 TAIWAN

886-7-621 6851~2

886-7-622 3595

Please login

Model / Specification

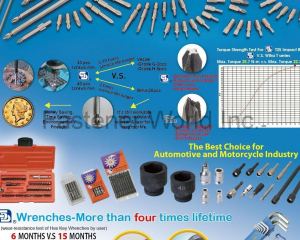

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

Country of Origin

TAIWAN

Surface Treatment

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

Material

Stainless Steel, Alloy, Mild Steel, Aluminium Allo

Alias

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

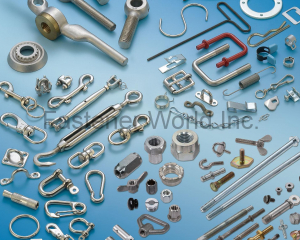

Hex-key Wrenches

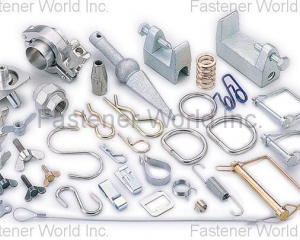

Nautical Hardware

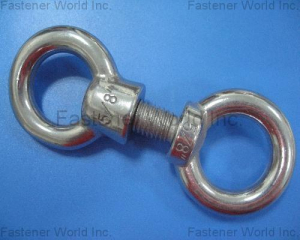

Eye Bolts

U Bolts

Screwdriver Bits

Nut Setters

Hand Tools

Turning Parts

Cnc Machining Parts

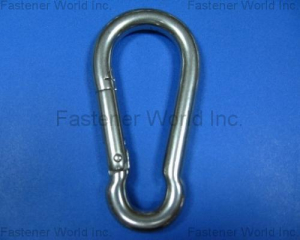

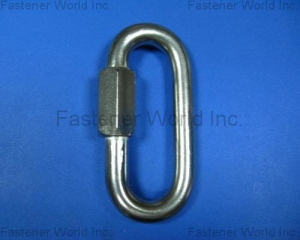

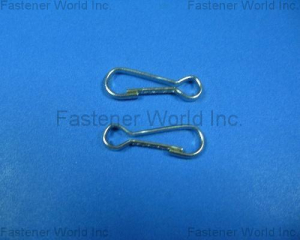

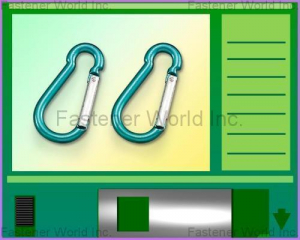

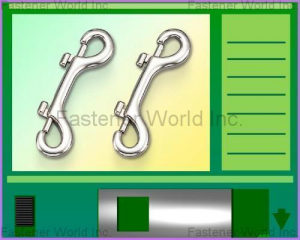

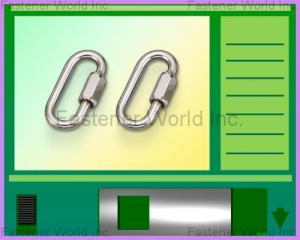

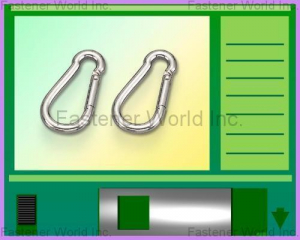

Hooks

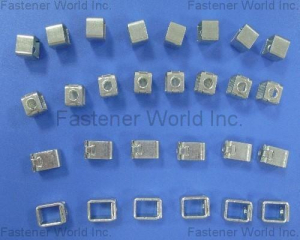

Clamps In General

Patent

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

Head Marking

Capacity

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

Minimum Order Quantity

Hex Key Wrenches, Power Bits, Amazing / Excellent Series Tools

Detailed Description

Shun Den Iron Works Co., Ltd.Decades of Expertise Drive the Maker’s Diversificationhttp://www.shun-den.com.tw/ Backed by some 30 years of expertise in heat treatment, Shun Den Iron Works Co., Ltd. has diversified into hex-key wrenches, aiming to be a world-caliber, top-end supplier of hex-key wrenches. Driven by End-user Demand Driven by end-user demand for high-quality hex-key wrenches, it decided to venture into the sector in 2009 after several decades of forging, die casting and stamping work, tapping such seasoned skills and know-how of heat treatment to develop high-quality hex-key wrenches. It spent over one and half years focusing its R&D on top-end products from Germany and Japan, as well as studying users’ experience in machinery and mold maintenance, and ultimately figured out a solution for the technical dilemma of balancing structural flexibility and surface hardness, which has not been addressed in most wrenches sold in different markets. It says that wrenches sold in Europe are moderately hard, being rated between 50 and 53 and structurally flexible but prone to wear, compared to those from Japan and Taiwan that are high-HRC-processed, hardness-rated between 56 to 62, though more easily fatigued to be more dangerous to users. To build a better product, it has applied special heat treatment to overcome the problem, hence developing its line of superb quality, professional-grade hex-key wrenches. Highest Criteria It claims that each batch of hex-key wrenches is sample-tested according to a full process to ensure the highest structural flexibility, lifespan and wear-resistance.It first tests surface hardness in compliance with requirements, making sure the HRC ratings for ones of chrome vanadium steel and S2 steel reach min.53 and min.56, respectively. The next is the destructive test where it’s QC technicians overload a DIN 12.9-grade hex socket cap screw, ensuring that the wrench remains structurally robust, while each of the six edges is undamaged and untwisted. Eventually, the tested wrenches are fixed firmly and turned 90 degrees for further fatigue, and then only the ones causing no structural fracture can be delivered to customers.

Message Board