SUN THROUGH INDUSTRIAL CO., LTD.

About Company

SUN THROUGH INDUSTRIAL CO., LTD.

TAIWAN

NO. 39, ALLEY 90, LANE 1, SEC. 6, LUHE RD., HEMEI TOWNSHIP, CHANGHUA COUNTY 50846 TAIWAN

886-4-757 6060

886-4-757 6080

Please login

Model / Specification

Country of Origin

TAIWAN

Surface Treatment

Material

Alias

Patent

Head Marking

Capacity

Minimum Order Quantity

Detailed Description

Sun Through Industrial is recognized by the industry as a professional manufacturer of self-tapping/drilling screws, high strength bolts, drywall screws, chipboard screws, etc., with strong customization capability, continuous development of new construction fasteners, and innovation & quality on par with int’l standards. Always serving from the technology-based perspective, Sun Through can provide more cost-effective fastening solutions for customers with more difficult or complex product requirements. Not only is it a key partner for many European and U.S. customers seeking customized services, but it has also created a unique competitive advantage by staying ahead of competitors.

Key-point Improvements with Performance Better than Counterparts;

Self-drilling Screws for Hollow Cement Bricks to be Showcased at Fastener Taiwan 2024

Spiral-type self-drilling screws, bi-metal screws, and high strength bolts are Sun Through's most competitive products and have been proven by customers to significantly improve technical and operational issues in real-world applications.

The main carbon steel or bi-metal spiral-type self-drilling screws feature faster iron scrap discharge, allowing users to easily penetrate steel plates up to 30mm thick. These products are available in sizes as small as 5.5mm and as large as 8mm and in lengths ranging from 50-350mm. The superior tapping performance provides customers with additional options, and products with a thickness of 8 mm can replace conventional structural bolts. “Our spiral-type self-drilling screws are more difficult to make than ordinary ones. We are also one of the few manufacturers that can satisfy customers’ needs of tapping thicker plates," said Sun Through. Considering the increasing market demand for bi-metal screws, Sun Through has also made in-depth improvements to the critical welding process, making the strength of welded joints not only better than the laboratory requirements but can even be twisted and bent, which once and for all solves the problem of insufficient torsion when customers are using long screws for board tapping and are also subjected to gravitational loads. Sun Through has also successfully developed a Gr. 14.9 screw, which has a fatigue life 50% more than that of 12.9 screws. The feature of no brittle fracture has allowed it to enter the supply chain of U.S. EV and European heavy motorcycle & machine manufacturers.

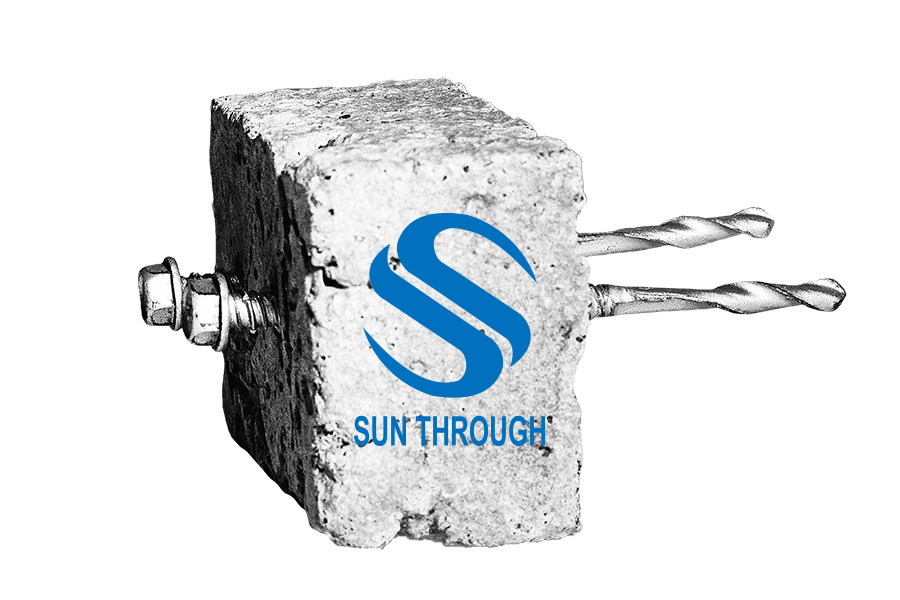

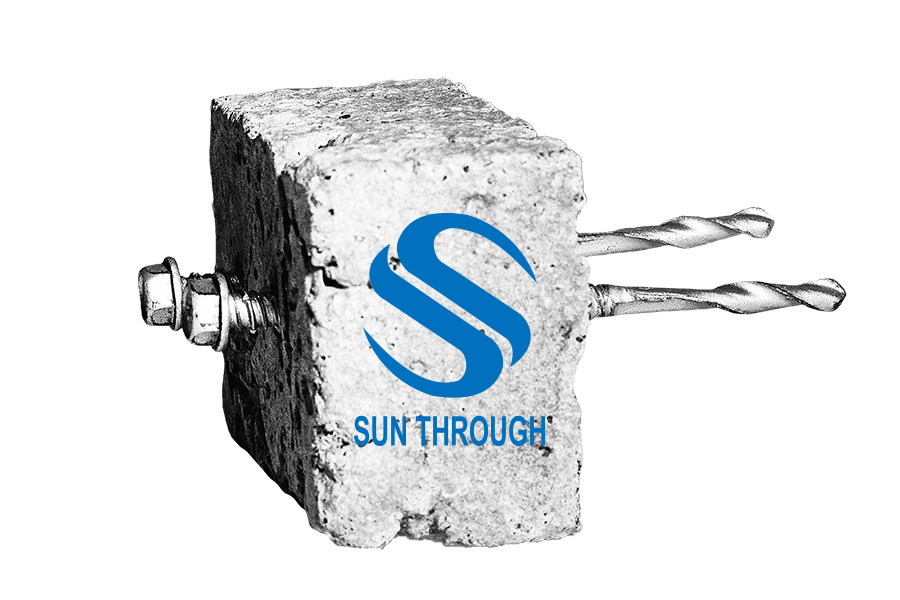

Recently, Sun Through has announced that it will be releasing self-drilling screws for hollow cement bricks, which will be officially revealed at this year's Taiwan International Fastener Show (Fastener Taiwan). The traditional self-drilling screws for hollow cement bricks require drilling holes and using screws to complete fastening. In addition to the complexity of the workmanship and tools required, the diameters of holes and sizes of screws must also be taken into account, but this new product from Sun Through can directly tap into the wall, greatly saving users’ fastening time and effort.

Process Improvement for Advanced Applications

In response to the global trend of carbon reduction, Sun Through has been conducting its carbon inventory and expects to make comprehensive improvements to the more energy-consuming heat treatments in manufacturing. Simultaneously tapping into the construction and automotive markets, Sun Through will also work with customers to develop fasteners for concrete materials related applications, and conduct management upgrades in response to PPAP requirements. "PPAP is a basic requirement for entering the automotive market, and we’ll do a good job of management upgrades in order to prepare for entry into the higher-end market. We sincerely invite you to visit our booth during Fastener Taiwan," said Sun Through.

Key-point Improvements with Performance Better than Counterparts;

Self-drilling Screws for Hollow Cement Bricks to be Showcased at Fastener Taiwan 2024

Spiral-type self-drilling screws, bi-metal screws, and high strength bolts are Sun Through's most competitive products and have been proven by customers to significantly improve technical and operational issues in real-world applications.

The main carbon steel or bi-metal spiral-type self-drilling screws feature faster iron scrap discharge, allowing users to easily penetrate steel plates up to 30mm thick. These products are available in sizes as small as 5.5mm and as large as 8mm and in lengths ranging from 50-350mm. The superior tapping performance provides customers with additional options, and products with a thickness of 8 mm can replace conventional structural bolts. “Our spiral-type self-drilling screws are more difficult to make than ordinary ones. We are also one of the few manufacturers that can satisfy customers’ needs of tapping thicker plates," said Sun Through. Considering the increasing market demand for bi-metal screws, Sun Through has also made in-depth improvements to the critical welding process, making the strength of welded joints not only better than the laboratory requirements but can even be twisted and bent, which once and for all solves the problem of insufficient torsion when customers are using long screws for board tapping and are also subjected to gravitational loads. Sun Through has also successfully developed a Gr. 14.9 screw, which has a fatigue life 50% more than that of 12.9 screws. The feature of no brittle fracture has allowed it to enter the supply chain of U.S. EV and European heavy motorcycle & machine manufacturers.

Recently, Sun Through has announced that it will be releasing self-drilling screws for hollow cement bricks, which will be officially revealed at this year's Taiwan International Fastener Show (Fastener Taiwan). The traditional self-drilling screws for hollow cement bricks require drilling holes and using screws to complete fastening. In addition to the complexity of the workmanship and tools required, the diameters of holes and sizes of screws must also be taken into account, but this new product from Sun Through can directly tap into the wall, greatly saving users’ fastening time and effort.

Process Improvement for Advanced Applications

In response to the global trend of carbon reduction, Sun Through has been conducting its carbon inventory and expects to make comprehensive improvements to the more energy-consuming heat treatments in manufacturing. Simultaneously tapping into the construction and automotive markets, Sun Through will also work with customers to develop fasteners for concrete materials related applications, and conduct management upgrades in response to PPAP requirements. "PPAP is a basic requirement for entering the automotive market, and we’ll do a good job of management upgrades in order to prepare for entry into the higher-end market. We sincerely invite you to visit our booth during Fastener Taiwan," said Sun Through.

Message Board