August Highlights: Chin Tai Sing & Linkwell Industry

With monthly capacity of 10 million pieces, Chin Tai Sing Precision Manufactory uses fully traceable production management to manufacture high quality threaded inserts & self-clinching fasteners, and has made a reputation and is regarded as a top supplier in the global automotive and electronic parts markets. Linkwell as a one-stop fastener hub offers global clients stable supply of fasteners through plants in Vietnam, Malaysia, Indonesia, Thailand, China and Taiwan while it enters the 46th year of business.

World Recognized Chin Tai Sing

Threaded Inserts & Self-clinching Fasteners

This is attributed to several of its features including:

-Fully traceable production management with top-level QC;

-Excellent manufacturing technique, experienced customer service staff, market-leading products that are good value for the price;

-Pursuit of 0 PPM production quality;

-Certified to ISO 9001 and IATF 16949, two of the major certification systems.

Automotive & Electronics Clients’ Favorite

For decades, Chin Tai Sing Precision Manufactory has made achievements in the American and European markets. It supplies standard and customized brass threaded inserts, metallic self-clinching studs and nuts, as well as parts in various materials including stainless steel and aluminum. It has made a reputation and is highly regarded as a top supplier in the global automotive and electronic parts markets.

Stringent Manufacturing Process, Automated Equipment, Full Traceability

The company’s monthly capacity reaches 10 million pieces which can cope with the vast order demand from clients all over the world. It can provide RoHS certificates, PPAP documents, and IMDS as well as ISIR reports. The reason that it can create world-class high quality products trusted by clients, is because its production line complies with ISO 9001 and IATF16949 standards, and because it has technicians with over 20 years of experience who can swiftly solve and prevent quality anomalies. Furthermore, the company has advanced visual measuring instruments, optical sorting machines and packing machines to cope with clients’ quality requirements and specific requests.

General Manager Johny Lee said, “Besides, we are the first in the industry to have introduced full traceability in our production process to let clients trace order status with ease. We follow a strict quality policy and we monitor quality for clients from checking materials to the final shipment. We stick to quality and we don’t back off. We apply 0 PPM standard to products purchased by clients. We also ask the same to be applied to related staff, equipment, and service to create price competitiveness and top quality products for clients.”

Going for High End: “Our Mission is to Satisfy High-end Clients”

“It’s either capacity or quality that clients care most about.” The company’s strength has been satisfying high-end clients with high quality and efficiency. Lee stressed that he will continue to develop higher-end precision products with tolerances below ± 0.01 in the future to create higher-end brand values for clients.

Clients’ demand across the global market continues to change, and the company faces head on with new trends and challenges. It will introduce more advanced automated production and inspection equipment, continuing to improve its production efficiency and product yield rate. Chin Tai Sing will lead its experienced technical staff and provide high level customer service, and dedicate itself to becoming the unbreakable support for clients and the industry.

Contact: General Manager, Mr. Johny Lee

Email: inquiry@ctsp-insert.com.tw

---------------------------------------------------------------------------------------

Linkwell

Stable Growth & Supply for Global Fastener Demand

Founded in 1977, Linkwelll has walked through 45 years and now into the 46th year. It was one of the pioneers dedicated in fastener trade back when Taiwan fastener industry was taking form. Extending to fastener manufacture and utilizing both roles as a manufacturer and trader, it is known as a one-stop fastener hub. Its assorted range of fasteners guaranteed with Taiwanese credibility and quality are supplied to the machinery, automotive and construction industries. Linkwell has manufacturing plants in Vietnam, Malaysia, Indonesia, Thailand, China and Taiwan, and a majority of customers from the U.S., Europe, and Japan.

Major Manufacturing Factories Overseas

The reason that it can be a reliable supply source for clients is because it is rooted in Taiwan and extends to Southeast Asia and China. All of its overseas plants support one-stop and streamlined production with stable quality, starting from material handling to production, processing, electroplating, packaging, inspection and delivery.

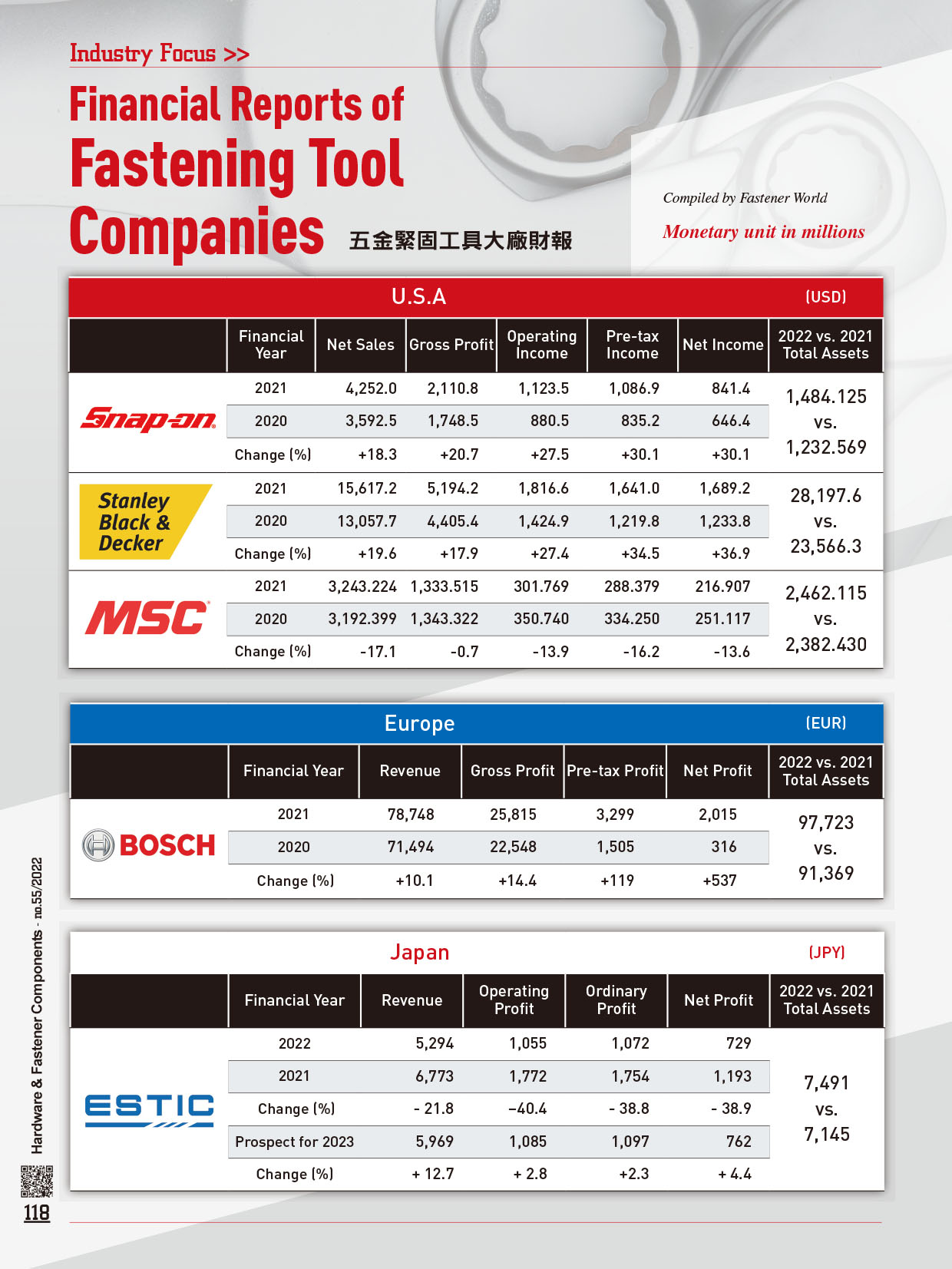

Each of Linkwell’s plant is characterized as in Table 1. The Vietnam and China plants feature carbon steel screws (Vietnam: mostly small screws and self-drilling screws; China: mostly large bolts). The Indonesia and Malaysia plants mainly manufacture stainless steel screws (Indonesia: mostly standard screws; Malaysia: mostly special screws). The Vietnam plant began production 5 years ago and is now full-fledged with a full process from heading to threading, slotting, heat treating and electroplating completed under stringent quality control. This plant continues to gain additional orders. Each plant above comes with a feature and competitiveness that are recognized by buyers.

Beginning in 2020, the market took a hit from the pandemic and was particularly at its lowest in April to June 2020. It started to pick up in July, and in October 2020, various industries were faced with clients’ revenge spending. Prices of all materials and particularly shipping heightened. Everyone seemed afraid of the shortage and this phenomenon lasted for astounding one and a half years.

And then the fourth month of 2022 became a turning point. Clients had been overstocking, the prices were too high and the pandemic came back. Plus, with Russia-Ukraine war, market demand took a plunge and drastically changed the world’s business. All material and shipping prices started to come down. (The inflation, however, is an existing fact and supposedly the price will not go down to the point it initially rose from.)

“Our only path in response is to change our structure to further automate production, lower operating costs, manufacture higher-value special products and enhance collaboration with clients so that we can work together to create a better future.”

Table 1.

Regions

Malaysia

Indonesia

Vietnam

Pinghu City (Zhejiang Province of China)

Plant Name

Well Union Metal Sdn. Bhd

PT. Batam Well Industry

Viet-Screw Company

Fastwell Industry Co., Ltd.

Area

9,000 Sq m.

12,000 Sq m.

32,000 Sq m.

20,000 Sq m.

Equipment

42 heading machines

4 forming machines

50 heading machines

2 forming machines

70 heading machines

15 heading machines

10 forming machines

Monthly Capacity

180-200 tons

200-250 tons

1,200 tons

1,000 tons

Product

Mainly stainless steel (A2、A4、410 SS) screws and small screws.

Self-drilling, chipboard, drywall, self-tapping, machine screws, and bolts below (including) Ø M10.

Mainly stainless steel (A2、A4、410 SS) screws and small screws.

Self-drilling, chipboard, drywall, self-tapping, machine screws.

Mainly carbon steel and small screws.

Self-drilling screws, chipboard screws, drywall screws, collated screws, self-tapping screws, concrete screws.

Carriage bolts (DIN 603), hexagon head screws, flanged bolts, machine screws.

Diameter

M2.5-M12

M2.5-M8

M2.5-M10

M2.5-M20

Length

4mm-150mm

4mm-150mm

12mm-320mm

6mm-300mm

(Viet-Screw Company)

(Well Union Sdn. Bhd.)

(PT. Batam Well Industry)

(Fastwell Industry Co., Ltd.)

Contact person: Ms. Paggy Chen

Email: paggy@linkwell.com.tw

----------------------------------------------------------------------------------------