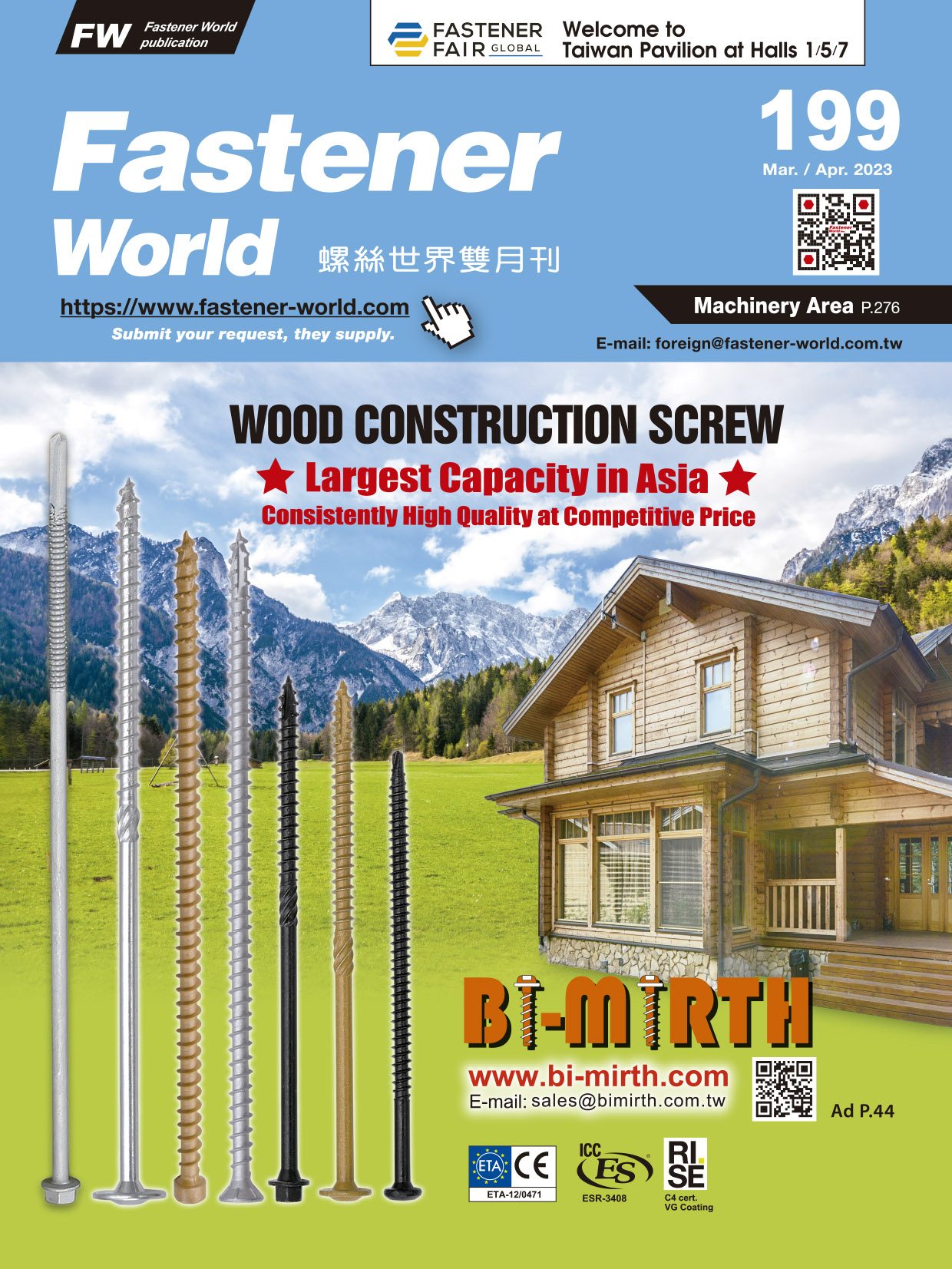

Bi-Mirth Special Purpose Long Screws Available Now in 3 Types

Bi-Mirth specializes in the R&D, production and export of structural wood and concrete fasteners, of which 25% are exported to the U.S., 70% to Europe and 5% to other countries including Brazil and Japan. Soon after they announced an update on their U.S. ICC certificate, electroplating line, electroplating liquids and coatings last September, they are now featuring three special products this spring and have embarked on a full-range sale promotion in the Fastener Fair Global and Taiwan International Fastener Show. This cover story takes a dive in the features of Bi-Mirth hardwood screws, timber-concrete connector screws, and A2/A4 stainless steel wood screws, and ends with a scoop on Bi-Mirth’s carbon reduction arrangements in response to the EU carbon tax.

Hardwood Screws

Handle Even the Most Stubborn Wood like a Breeze

Traditionally, timber constructions usually use softwoods, but recently more and more countries are using hardwood as a building material. Hardwood uses less surface area to achieve equal or higher performance than softwood. Regular screws could break when drilling into hardwood due to its high density. Bi-Mirth did intensive research on hardwood and rolled out a screw made with a specific material and heat treatment technology to cope with the high density in hardwood. This special screw is characterized by low insertion torque and no breakage during installation.

Timber-Concrete Connector Screws

There are many old houses in various countries that are in high demand for renovation. Wood is resilient (very flexible) and delivers good shear resistance (not easy to break); concrete performs better in resisting pressure. The use of both concrete and timber in the renovation process can bring out the advantages of both materials. In addition, this solution creates better acoustic effect in the building. Bi-Mirth has developed a suitable solution for timber-concrete connection that prevents displacement between the two materials and provides excellent shear resistance.

A2/A4 Stainless Steel Wood Screws

Born to Tackle Harsh Environments

The BM Quickdrill wood screw series now adds stainless steel as a material option. A2 304/305 and A4 316 stainless steel deliver extraordinary resistance against high salinity and acidic environment. High rust and corrosion resistance makes it ideal for use in harsh environments near the sea to maximize the combined effect.

New Products Soon to be ETA Certified

All these three screws are available for customized production and Bi-Mirth has already applied for ETA certification.

Towards Carbon Reduction and Green Manufacturing

The EU carbon border tax has spurred a lot of discussion in the fastener industry in Taiwan. With a focus on the European market, Bi-Mirth devotes a lot of attention and preparation to carbon reduction and green manufacturing. They have installed solar panels on the roof of their own electroplating factory and are planning to make green electricity in the future. Bi-Mirth’s forming, coating, and packaging plant will also be planning to build solar power in the near future. In addition, they have introduced electrostatic oil-filtering devices in their screw manufacturing plant to significantly reduce fume emissions in the plant.

The Importance of Carbon Reduction

At present, the common ways to reduce carbon include planting trees, installing solar panels, or converting heat into electricity in the production process of machines. However, in the face of the carbon tax which will be imposed by the European Union by 2027, will the existing practices be able to respond? In this regard, Bi-Mirth calls on the Taiwanese fastener industry to pool their ideas and develop innovative ways to reduce carbon in the fastener industry. For example, study how to reduce carbon emissions in material selection, manufacturing process, outsourcing, cleaning, inspection, packaging, logistics and other aspects. Or, think about how to pull out vertical collaboration through Taiwan’s unique strong screw supply chain, or how to learn horizontally and introduce carbon reduction technology from other different industries. These are the issues we can think about immediately.

In addition, there are still a lot of details up in the air regarding the current carbon tax. When the tax starts to be levied, Taiwan fastener traders will need a set of benchmarks to determine whether their partner suppliers meet the carbon emission standards. Bi-Mirth points out this aspect also deserves the industry’s attention.

What’s Next for Bi-Mirth

Bi-Mirth believes that the next focus on carbon reduction is timber buildings. Steel and concrete building creates more carbon from raw material to the construction of the building comparing to timber building. Traditionally, people have a misconception about the safety of the timber building; however, new technologies for timber constructions make timber buildings safer. Timber buildings can bear both horizontal and vertical shock waves, and are more resistant to earthquakes than steel buildings. In addition, fire safety is greatly improved in timber constructions. Bi-Mirth will continue on its path of wood screw development and continue to make innovative products.

Contact: Bi-Mirth Sales Team

Email: sales@bimirth.com.tw