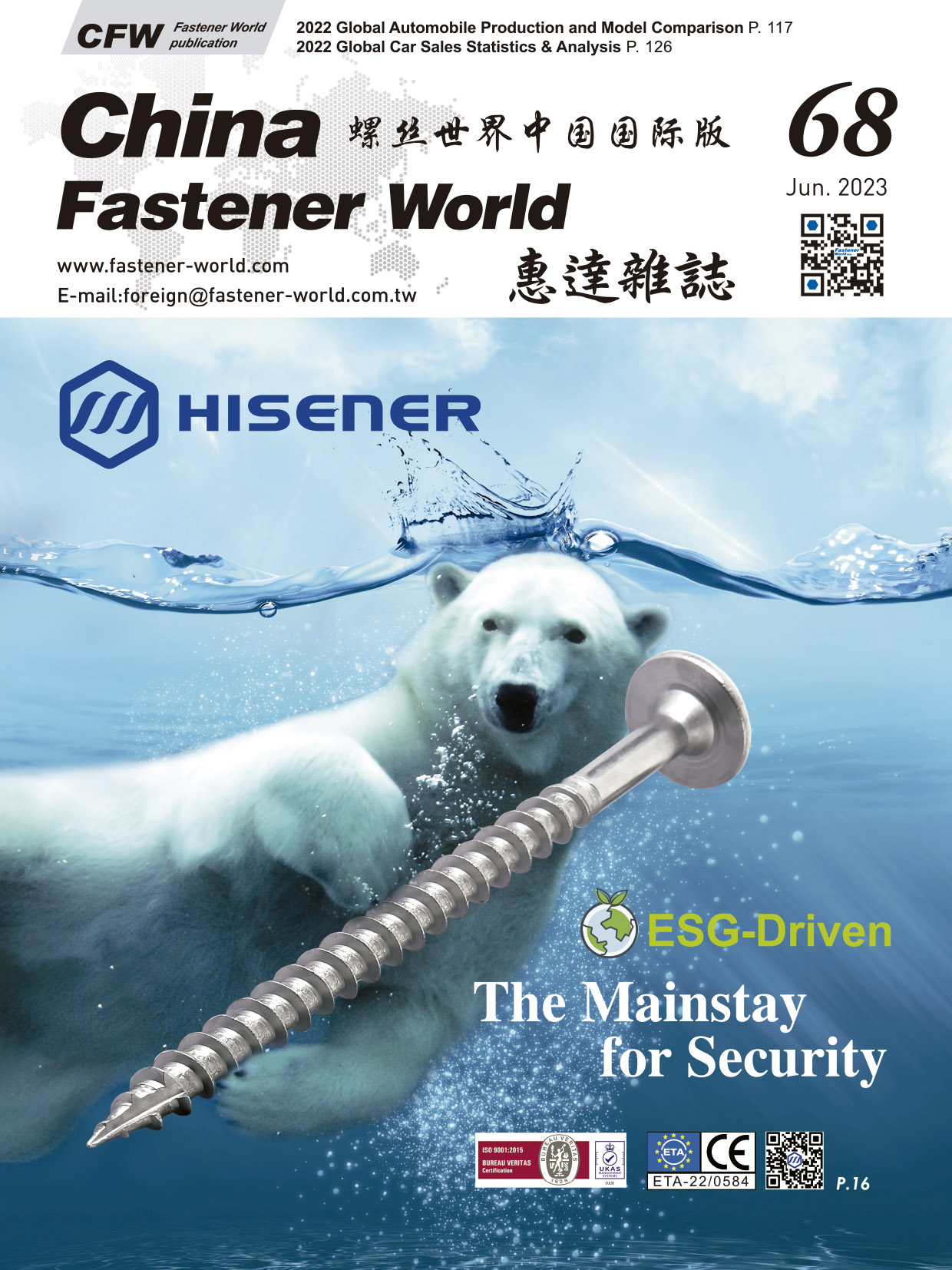

Eyeing Global Market Share with Stainless Steel Screws, Hisener Industrial on a NEW Journey

Hisener has become a benchmark Chinese manufacturer and one of the largest fastener suppliers in the world, working with 150 carefully selected partners to supply over 4,000 types of fasteners to customers in Europe, the U.S., South America, and Russia. Even though the pandemic once prevented face-to-face communication with customers, Hisener has been achieving major breakthroughs in the last two years. New products, capacity upgrade, automation and digitalization are Hisener’s keywords for 2023!

New Market Share for Stainless Steel Products

The new 32,000 square meter factory completed in the third quarter of last year has added a new manufacturing area for stainless steel products. Stainless steel screws have always been a product that Hisener wanted to produce in-house. The new plant is a significant milestone since its establishment, as it is enlarged in area and equipped to produce this product. With years of experience in manufacturing, Simon Liang, the manager, has a deep understanding of the characteristics of stainless steel products and has mastered the best balance between drilling performance, price and cost. He believes his rollout of convenient one-stop purchasing will enable his products to gain market shares in the global market.

Triple Production Capacity

Hisener’s new factory has more than 300 machines, including 140 1-die-2-punch heading machines, 2 multi-stroke machines, 130 thread rolling machines, 8 self-drilling screw machines and 15 slotting machines, all imported from Taiwan. The 150 employees in the factory can manufacture 1,500 tons of screws for customers every month, significantly surpassing the previous production capacity of 500 tons.

Automation for High Speed and Stable Supply

The new factory includes a wire rod warehouse, semi-finished products warehouse, and finished products warehouse. The automated and digitalized connection between each warehouse and the production process achieves the upgrade to a smart factory. After connecting to ERP and WMS, every process can complete automatic material loading, significantly reducing labor and transportation costs and improving the operational efficiency of the factory. Customers will feel Hisener’s delivery becomes faster. The birth of the new factory is to provide customers with higher value-added products at better prices and bring elevated values to customers.

Larger Laboratory to Ensure Quality and Quantity

The new factory is equipped with a larger laboratory encompassing inspection equipment for dimensional analysis, composition analysis, metallurgical analysis, mechanical property analysis, surface treatment analysis and so on. The lab has 10 employees to master all aspects of products from material to production process, ensuring that each batch is strictly inspected and traceable.

Global Footprint and Further Communication with Global Customers

Simon noted the prospect for positive market demand development is up again, and he is doing his best to travel around the world to communicate with customers face to face, to better understand their pain points and difficulties, and to solve their problems through new products and the upgraded new factory. He also welcomes all customers to come to China to witness the transformation and upgrade of his new factory, further the bond of trust and expand collaboration!

Contact: Simon Liang

Email:simon@hisener.com