U-Chance Releases New Patent and Receives AS9100 Approval

Lightweight Metallic Fastener Manufacturer

U-Chance Releases New Patent and Receives AS9100 Approval

by Tanya Shih, Fastener World Inc.

U-Chance Enterprises Co., Ltd., well-known for its specialty in production of fasteners made of lightweight metals (e.g. Magnesium, Aluminum, and Titanium) once again released good news to the industry. In response to the demand for lightweight parts of major car manufacturers around the world, U-Chance, despite the complexity in handling metallurgical properties of certain metals, successfully developed the long screws made of 6061 and 7075 Aluminum, which not only helped its customers achieve the aim at weight reduction, but were also patented in several countries. On the other hand, U-Chance started to carry out the procedures required by the certification of AS9100 in 2013 and was officially certified by AS9100 in November 2014, making it one of the approved suppliers for aerospace fasteners.

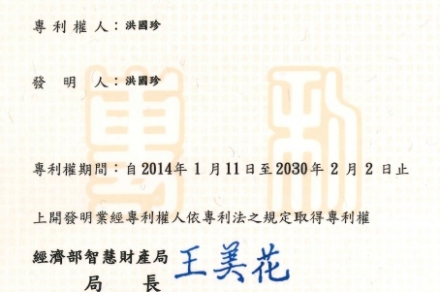

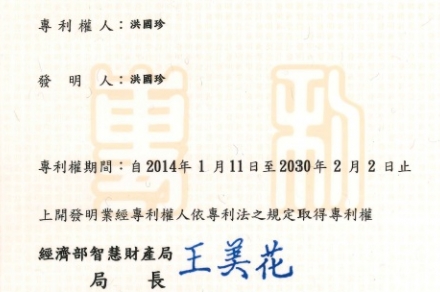

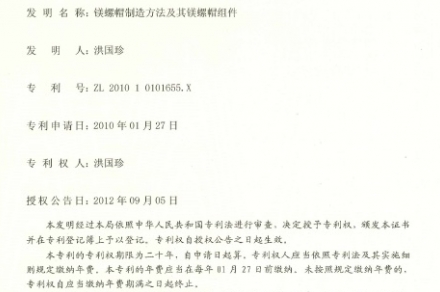

The World’s First Patented 200mm Long Screws (Made of 6061 and 7075 Aluminum)

U-Chance, with a 10% annual growth, has received the approval of ISO 9001, ISO 14001, and TS 16949 and its main business is production of carbon steel custom-made automotive fasteners and precision fasteners, representing up to 90% of its total business. 2 years ago I once called General Manager Hank Hung “The Man with an R&D Brain” when he was first appointed by his family to manage the company. Despite that Hung had a very promising career in the IT industry before he changed his business to fasteners, he never succumbs to defeat and has a great passion for R&D and taking challenges.

Every metal has its own properties. For example, aluminum is light and soft, so many companies are able to manufacture small and precision aluminum screws, but may be unable to make a great deal of investment in developing long aluminum screws. U-Chance, however, goes on a different way and such a difficult task is one of the favorite things General Manager Hung would really love to do. He said, “You can say that the development of products made of expensive metals is only for pulling a stunt, or just a crazy thing to do. Even so, the traditional industry can be very high end, too.” With such a thought in his mind, he then developed the 200mm aluminum long screws for the automotive industry. Asked about how to maintain steady growth with great spending on R&D every year, Hung said frankly, “Our growth resulted from the new forging method we found to replace CNC machining, helping customers save costs and making the company receive more orders.”

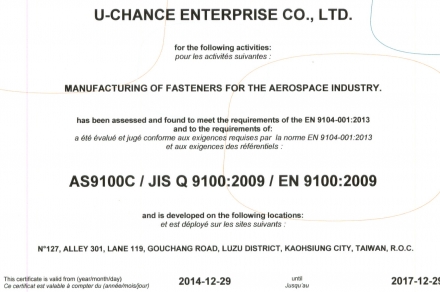

Becoming One of the AS9100 Approved Fastener Suppliers with Pride

Being approved by AS9100 is another good news for U-Chance after one and half years of verification, which means the company has successfully become one the approved suppliers for aerospace fasteners. After receiving the certificate, Hung particularly pointed out, “Many wrong considerations are often observed in the industry and receiving the approval of AS9100 is mistakenly regarded as being very hard. For companies which have been approved by TS16949, I don’t think it will be difficult for them in being approved by AS9100.” He added, “There is not a well-developed aerospace industry in Taiwan, as a result, it will be another difficult road for automotive fastener suppliers to tap into the supply chain of aerospace fasteners. But being always geared up for everything is absolutely a right thing to do.”

U-Chance has the ability to developing new products and its products are mainly for custom-made demand and high-end engineering applications in European/US/Japanese markets. With the recently received AS9100 approval, U-Chance did establish a new milestone for itself. We truly look forward to another good news of this company to come.

Subscribe