Industry Activities

KWANTEX TTX® DRIVE SYSTEM

Add to my favorite

2021-01-18

The Breakthrough of Taiwanese Fasteners! A Complete Replacement for TX

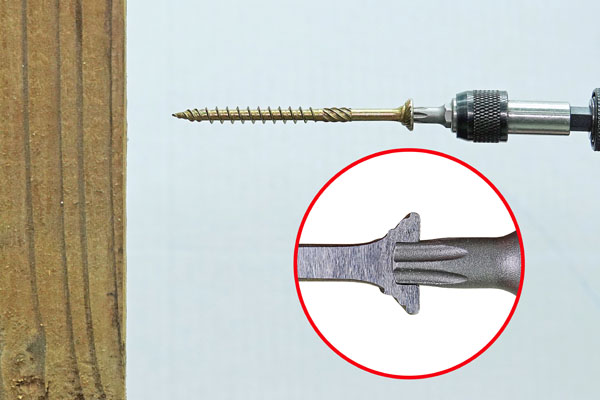

Taking a giant leap forward in the product R&D in 2020, Taiwan’s leading wood screw R&D-focusing manufacturer Kwantex Research Inc. has successfully developed the TTX® Drive System (Taiwan TX Drive System) featuring a 6-lobe drive with additional sharp hook design, which can completely replace the existing TX drive and is expected to create a new chapter in the global R&D and application field of wood screws, automotive screws and industrial assembly screws.

No More Disadvantages of the Old-fashioned Drives!

In the past, while users were fastening wood screws, they used to encounter some problems resulted from certain drive designs. For example, the bit did not fit well with the drive, causing unexpected wobbling, drive abrasion, or bit breakage. These problems not only prevented users from achieving expected tight fastening, but also resulted in the unnecessary waste of materials and tools. In such a market with fierce competition, any of these problems will gradually diminish the competitive edge of companies’ products. However, after Kwantex officially rolled out the new TTX® Drive and the mating TTX® Bit, all of the above worries can be eliminated and users can now achieve satisfying perfect fastening results.

● Unique Sharp Hook Design. No Cam-out!

Different from traditional Phillips or Pozi drive (which cam-out usually occurs due to its inclined contact surface, which cannot transfer sufficient torque to screws with larger outer diameters, or which is prone to drive abrasion while fastened) as well as TX, square, Phillips+Square, or socket hex (which the bit cannot fit tight with, insert deep, or which the drive abrasion may occur during fastening), Kwantex TTX® Drive can perfectly fit with TTX® Bit. It goes direct to the bottom and fits tight!

● Higher Torque Transfer

The specially developed sharp hook design allows the mating bit to transfer higher torque, thus users can even fasten screws with only one hand, which is both time and force saving, not to mention that inexperienced users can also finish fastening easily. Kwantex TTX® Drive System is not only applicable to wood screws, but also is applicable to screws for penetrating construction steel and machine screws for steel structure & industrial assembly. Its application range is quite comprehensive.

● 4 Times Longer Service Life

TTX® Bit has a similar design of 6 lobes with additional sharp hooks. On each lobe of the drive, there is a special sharp convex to help achieve tight fastening, avoid slippage, increase the contact surface between the drive and the mating bit, reduce stress accumulation, and optimize torque transfer. The results of more than 10,000 times of torsion and breaking tests also reveal that compared to the traditional TX Bit on the market, the service life of TTX® Bit is greatly increased by 4 times. Its durability is self-evident. On the other hand, TTX® Bit can be also used directly to fasten TX drives of the same size number, showing a very high applicability.

Comparison Between TTX® Bit and TX Bit:

|

Bit Type

|

Max. Torque Delivery (N.m)

|

Fatigue Test

|

|

TX 25

|

18.99

|

Bit sustained 5,236 cycles before breakage

|

|

TTX 25

|

20.05

|

Bit sustained 22,977 cycles before breakage

|

Speaking of the newly released TTX® Drive System, Kwantex President Jack Lin said, “We are confident that the new product we rolled out this time will definitely be a game-changing one in the industry. Our goal is to produce a type of fasteners that are affordable to everyone and can be quickly and effectively used to fasten products made from various materials and treated with different surface finishes. The angle of the inclined surface of the drive has been meticulously calculated to ensure enough contact surface area and the extra well-engineered hook design, according to the wedge theory, has been also added to achieve stick-fit. Kwantex has been always dedicated to R&D and will continue to roll out more products with excellent design, as we hope to help Taiwanese fastener industry increase its value with the ever-changing market.”

Kwantex contact:

Ms. Tracy Lin (Assistant Vice President (Sales & Marketing))

Email: kwantex@ms18.hinet.net

寬仕

TTX(R) Drive System

取代梅花孔

TTX(R) BIT

replacement for TX

KWANTEX RESEARCH

扣件

國際展會

惠達雜誌

匯達實業

外銷媒合

廣告刊登

螺絲五金

五金工具

紧固件

台灣扣件展

印度新德里螺絲展

越南河內螺絲展

墨西哥瓜達拉哈拉螺絲展

美國拉斯維加斯螺絲暨機械設備展

波蘭克拉科夫螺絲展

義大利米蘭螺絲展

德國司徒加特螺絲展

wire Dusseldorf

FASTENER FAIR INDIA

FASTENER FAIR VIETNAM

FASTENER FAIR MEXICO

FASTENER POLAND

FASTENER FAIR ITALY

FASTENER FAIR GLOBAL

FASTENER WORLD

READ NEXT

Subscribe